Researchers from Wanida Wonsawat‘s group at Suan Sunandha Rajabhat University (Bangkok) and Takashi Kaneta‘s group at Okayama University recently published an article in Nature Research showing a relatively simple but elegant procedure to greatly increase the stability of hydrogen peroxide reagent absorbed into the fibres of the patterned Whatman filtre paper used the paper microfluidic devices in the study. Hydrogen peroxide is an oxidising agent that is often used in enzymatic assays that may create or remove a separate species that can be measured via indirect optical detection using colourimetry, fluorescence, chemiluminescence, etc.

Researchers from Wanida Wonsawat‘s group at Suan Sunandha Rajabhat University (Bangkok) and Takashi Kaneta‘s group at Okayama University recently published an article in Nature Research showing a relatively simple but elegant procedure to greatly increase the stability of hydrogen peroxide reagent absorbed into the fibres of the patterned Whatman filtre paper used the paper microfluidic devices in the study. Hydrogen peroxide is an oxidising agent that is often used in enzymatic assays that may create or remove a separate species that can be measured via indirect optical detection using colourimetry, fluorescence, chemiluminescence, etc.

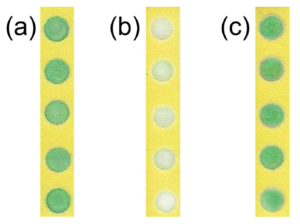

The paper microfluidic devices (or paper-based analytical devices, PADs) were created by with a commercial wax printer, and the exposed paper areas were treated with the colourimetric reagents. For these trials, simple circular areas were patterned for the proof-of-principle studies undertaken, in lieu of channel networks. The reagents used were 3, 3′, 5, 5′-tetramethylbenzidine (TMB, the substrate and also colourimetric reagent), bovine serum albumin (BSA), phosphate buffer and hydrogen peroxide, with or without the poly(vinyl alcohol) (PVA). Horseradish peroxidase (HRP, the enzyme ) was contained in the sample solution. TMB changes to blue in the presence of HRP and hydrogen peroxide.

The authors discovered that blue colour seen upon initial reaction faded after a day, and isolated the cause to decomposition of the hydrogen peroxide on the PAD during this time. The figure above shows PADs with the enzymatic assay occurring in the patterned dots, where a) both hydrogen peroxide and TMB were added to the PAD, and the results are captured shortly after reaction; or the PAD with only b) hydrogen peroxide or c) TMB is prepared and stored at room temperature for one day, and then the other reagents are added and the results captured. Degradation of the hydrogen peroxide causes the near total loss of signal in b).

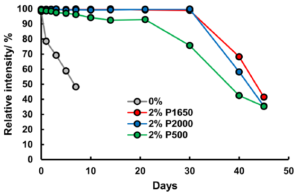

To stabilise the hydrogen peroxide, they added PVA to the hydrogen peroxide solutions prior to addition to the PAD, and found dramatic improvements in hydrogen peroxide stability. The extent of the improvement varying with PVA concentration and chain length, as well as storage temperature. 2% solutions of PVA with a length of ~1650 monomers extended the life of the reaction at ~100 intensity to 10 days with storage at room temperature, while refrigeration at 4°C extended that to 30 days for PVA lengths of ~1650 or 2000 monomers. The PVA is thought to protect the hydrogen peroxide by forming a liquid- and air-tight barrier, thus preventing attack by hydroxide anion that catalyses the degradation.

To stabilise the hydrogen peroxide, they added PVA to the hydrogen peroxide solutions prior to addition to the PAD, and found dramatic improvements in hydrogen peroxide stability. The extent of the improvement varying with PVA concentration and chain length, as well as storage temperature. 2% solutions of PVA with a length of ~1650 monomers extended the life of the reaction at ~100 intensity to 10 days with storage at room temperature, while refrigeration at 4°C extended that to 30 days for PVA lengths of ~1650 or 2000 monomers. The PVA is thought to protect the hydrogen peroxide by forming a liquid- and air-tight barrier, thus preventing attack by hydroxide anion that catalyses the degradation.

The importance of extending reagent lifetimes in microfluidic devices is a critical building block for the development of point-of-care/use devices. In this case, isolation and stabilisation of the hydrogen peroxide reagent, in widespread use for enzymatic assays, is of obvious benefit. 30 days of refrigerated storage is much better than a few hours, but a long way from the requirements for a robust product with a minimum 6-month shelf-life. However, one could imagine product development efforts with currently available packaging technology, e.g. desiccation followed by vacuum packaging or dry inert gas packaging, might easily eliminate the moisture-catalysed degradation, and thus extend product life significantly. There are also other stabilising polymers to choose from that may be better optimised for other types of reagents requiring a liquid/gas barrier.