The Microfluidics Association is participating in a workshop on November 13th-14th, 2023 focussed on on metrology in microfluidics, and hosted by the metrology wing of the French Cetiat institution. In preparation, we at the Microfluidics Association (I’m on the Board) want to brush up on what the microfluidics community wants and needs as regards metrology. Here’s a letter from Henne van Heeren, fellow board member.

“For our work in developing standards and metrology protocols it is crucial that we know what the community needs. Therefor you you are invited to participate in our survey concerning prioritizing metrology and standardization work for the coming years.

Your participation in this study is completely voluntary, so if you feel uncomfortable answering any questions, you can skip questions or withdraw from the survey at any point.

The information you will supply will be coded and will remain strictly confidential.

Thank you very much for your time and support. Please start with the survey now by clicking on https://www.surveymonkey.com/r/D6RF9JM

This survey is held in preparation for the November workshop “on the road to standardization in microfluidics and organ-on-chip”. For more information on this workshop, please click here.

Best regards on behalf of the Microfluidics Association

Henne van Heeren

henne@enablingMNT.com

0031 78 6300748

Download our published whitepapers: https://microfluidics-association.org

We acknowledge the support of the MFMET project, https://mfmet.eu/ and the European Metrology Programme for Innovation and Research: EMPIR.”

On behalf of the Microfluidics Association, I would like to encourage any and all working in microfluidics to provide your input about metrology via our survey. I gave my 2¢ this morning! 🙂

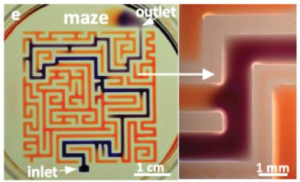

The authors have done a nice job of characterising the various parameters relevant to creating walls or features from the fluorocarbon, such as jet nozzle height, diameter, flow rate, lateral speed, wall thickness and channel widths. The ability to pipet into enclosed chamber arrays was also explored in terms of volume ranges and resistance to cross-contamination. Preliminary cloning studies with different cells suggested comparable cloning efficiency vs. normal Petri dishes without fluorocarbon structures.

The authors have done a nice job of characterising the various parameters relevant to creating walls or features from the fluorocarbon, such as jet nozzle height, diameter, flow rate, lateral speed, wall thickness and channel widths. The ability to pipet into enclosed chamber arrays was also explored in terms of volume ranges and resistance to cross-contamination. Preliminary cloning studies with different cells suggested comparable cloning efficiency vs. normal Petri dishes without fluorocarbon structures.