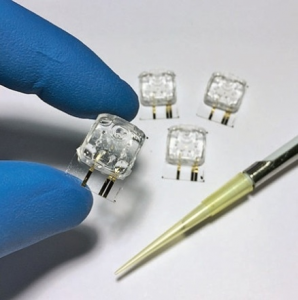

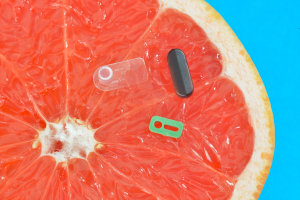

Fascinating research from the Qinghuang Lin lab at IBM Research in NY, published in Nature Communications and highlighted in Cytofluidix, shows an elaborate but potentially mass-producible microfluidic and nanofluidic lab-on-a-chip device that draws DNA molecules through arrays of nanometre-sized pillars. The DNA reptation in these structure stretches the molecules out, as in gel-based electrophoretic separations of DNA, and may enable identification of biomarkers that indicate diseases. The Cytofluidix summary page shows an engaging video of DNA migration through the pillar array.

Fascinating research from the Qinghuang Lin lab at IBM Research in NY, published in Nature Communications and highlighted in Cytofluidix, shows an elaborate but potentially mass-producible microfluidic and nanofluidic lab-on-a-chip device that draws DNA molecules through arrays of nanometre-sized pillars. The DNA reptation in these structure stretches the molecules out, as in gel-based electrophoretic separations of DNA, and may enable identification of biomarkers that indicate diseases. The Cytofluidix summary page shows an engaging video of DNA migration through the pillar array.

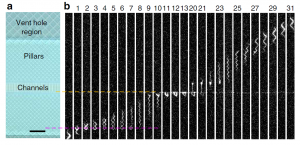

The research team had to overcome sizable challenges associated with the nanofabrication of the different structures that act as the DNA sieving medium. Researchers used a sacrificial silicon layer for the nanofluidic channels, and were able to overcome diffusion-limitted etching constraints by using temporary venting holes to accelerate the etching by 2 orders of magnitude. This process improvement may be the key to making the device a manufacturable product instead of a clever academic exercise.