I guess it’s not a big stretch to go from paper to wood for microfluidic substrates, but I’m impressed nonetheless! Govind Rao‘s group in Chemical Engineering at the University Maryland recently published an ASAP article in Analytical Chemistry (alternatively use this DOI) about microfluidic devices made in plywood.

I guess it’s not a big stretch to go from paper to wood for microfluidic substrates, but I’m impressed nonetheless! Govind Rao‘s group in Chemical Engineering at the University Maryland recently published an ASAP article in Analytical Chemistry (alternatively use this DOI) about microfluidic devices made in plywood.

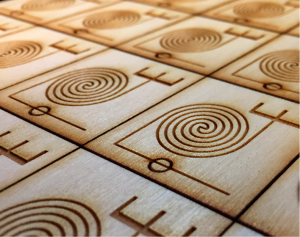

The Rao group machined channels and features in 35 chips laid out on 12″ x 12″ plywood sheets using a CO2 laser printer. Devices were treated with a 0.1-1% PMMA or Teflon solution to seal up pores and inhibit capilarity which would otherwise promote seepage of sample and running buffers in the substrate. Wooden channel layer substrate was bonded with cyanoacrylate glue to wooden cover plate with through-holes accommodating Luer lock fittings; PMMA covers were sometimes used for visualisation. Channels were ~0.68 mm-deep X 1 mm-wide, and the system tolerated pressures of ~2 psi. Different laser rastering speeds and line thicknesses were explored. Identical devices were made out of PMMA for performance comparison purposes.

Runs with blue and red food dye mixed at Y- and T-intersection mixers were performed and imaged to compare performance in a simple flow experiment. The figure at right shows comparable performance (PMMA in left column, wood in right column), though for both geometries, the wood chips do not provide an even amount of the two dyes (less red dye), and the signal is noisier, as shown by the black standard deviation lines above and below the red average signal lines. No discussion was found concerning these two discrepancies.

Runs with blue and red food dye mixed at Y- and T-intersection mixers were performed and imaged to compare performance in a simple flow experiment. The figure at right shows comparable performance (PMMA in left column, wood in right column), though for both geometries, the wood chips do not provide an even amount of the two dyes (less red dye), and the signal is noisier, as shown by the black standard deviation lines above and below the red average signal lines. No discussion was found concerning these two discrepancies.

The authors discuss the biodegradable advantage that wooden devices have vs. their polymer or glass counterparts, and how this is becoming increasingly important with new legislation banning single-use plastics coming into force in many jurisdictions.