A recent article in Nature: Microsystems & Nanoengineering by Ralf Hellmann’s group at the Aschaffenburg University of Applied Sciences and Thomas Walther’s group at the Technische Universität Darmstadt in Germany outlines impressive laser machined microfluidic microneedle devices.

A recent article in Nature: Microsystems & Nanoengineering by Ralf Hellmann’s group at the Aschaffenburg University of Applied Sciences and Thomas Walther’s group at the Technische Universität Darmstadt in Germany outlines impressive laser machined microfluidic microneedle devices.

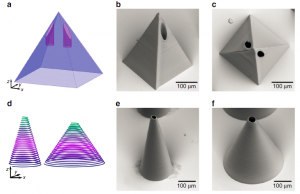

Devices were fabricated in PMMA coated in OrmoComp® photoresist in a two-step process. Direct laser written photoresist microneedle arrays (tip radius of 13-21 µm) and 3-D microfluidic PMMA channels were combined in a device using a single femtosecond pulsed laser for fabrication. The fabrication process is claimed to be simpler than traditional fabrication methods, but unfortunately, no throughput figures were provided. It would be nice to know what these are to understand how readily this fabrication technique could be applied as a manufacturing tool.

Devices were characterised with force vs. time curves for injections of a rhodamine B test solution through pork skin (which shares similar morphology to human skin) and to verify microneedle integrity during use.

The authors highlight that the devices could provide a significant leap forward for point-of-care applications including drug delivery and diagnostics.