A recent technical note in Analytical Chemistry from Professor Carolyn Ren’s lab at the University of Waterloo demonstrates an efficient and controlled approach for on-demand microfluidic droplet generation. The technique is used in a variety of important bio-medical and industrial applications such as: single or multiple cell sorting, culturing and incubation; droplet-based PCR and DNA sequencing; and chemical synthesis including micro- and nanoparticle synthesis.

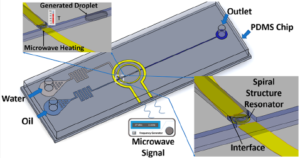

Microfluidic droplet generation at a tee intersection on a chip can be initiated or controlled by several approaches or factors such as balancing input pressures, channel intersection geometry, and surface tension at the interface. The latter offers an opportunity for fine control: input pressures for immiscible carrier and droplet fluids are nearly matched, and alteration of the surface tension and thus Laplace pressure at the interface meniscus will lead to on-demand droplet generation. Surface tension is a function of the chemical composition of the carrier and droplet fluids as well as temperature, so localised heating at the meniscus can enable fine control of droplet generation. On-chip resistive thermal heating works well, but has a slow response; laser cavitation is much faster, but requires expensive, delicate optically aligned off-chip instrumentation. The authors’ choice of on-chip microwave heating, shown at right above, has very rapid response times, is implemented with very simple (and cost-effective) microfabricated heating resonator electrodes, and affords precisely localised heating based on electrode design and chemically selective absorption of microwave energy by the aqueous droplet fluid (and not the carrier oil or PDMS device material).

Microfluidic droplet generation at a tee intersection on a chip can be initiated or controlled by several approaches or factors such as balancing input pressures, channel intersection geometry, and surface tension at the interface. The latter offers an opportunity for fine control: input pressures for immiscible carrier and droplet fluids are nearly matched, and alteration of the surface tension and thus Laplace pressure at the interface meniscus will lead to on-demand droplet generation. Surface tension is a function of the chemical composition of the carrier and droplet fluids as well as temperature, so localised heating at the meniscus can enable fine control of droplet generation. On-chip resistive thermal heating works well, but has a slow response; laser cavitation is much faster, but requires expensive, delicate optically aligned off-chip instrumentation. The authors’ choice of on-chip microwave heating, shown at right above, has very rapid response times, is implemented with very simple (and cost-effective) microfabricated heating resonator electrodes, and affords precisely localised heating based on electrode design and chemically selective absorption of microwave energy by the aqueous droplet fluid (and not the carrier oil or PDMS device material).

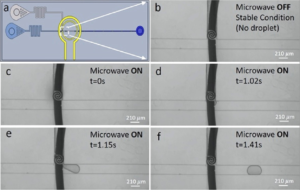

Time-lapsed photographs of droplet generation of water (vertical channel) in carrier oil (horizontal channel) using their system are shown at right below; the curved black line is the electrode under the vertical channel. The research showed a relationship between applied microwave power and generation time, but with droplet sizes remaining at a constant ~1.8 nL in their 40 µm deep x 210 µm wide channels.

Time-lapsed photographs of droplet generation of water (vertical channel) in carrier oil (horizontal channel) using their system are shown at right below; the curved black line is the electrode under the vertical channel. The research showed a relationship between applied microwave power and generation time, but with droplet sizes remaining at a constant ~1.8 nL in their 40 µm deep x 210 µm wide channels.

The advantage of repeatable, precisely controlled on-demand droplet generation for the many fields in which droplet-based microfluidics is used could be important. The fact that it should be manufacturable from different microfluidic device materials without expensive instrumentation is a considerable advantage as well. The localised nature of the heating could also be beneficial in thermally sensitive assays where excessive and/or prolonged heating is detrimental.