An interesting review of lab-on-a-chip devices made on flexible substrates was recently published in Lab on a Chip by Anastasios Economou and Christos Kokkinos at the University of Athens, and Mamas Prodromidis at the University of Ioannina. The authors cover devices made on polymer, paper and textile fabric substrates and which use electrochemical biosensing for detection. Lab-on-a-chip & microfluidic devices based on flexible substrates are very attractive given the low costs of the substrate and deposited materials, inexpensive and well established high volume manufacturing processes, and physical flexibility as an attribute for body-wearable devices.

An interesting review of lab-on-a-chip devices made on flexible substrates was recently published in Lab on a Chip by Anastasios Economou and Christos Kokkinos at the University of Athens, and Mamas Prodromidis at the University of Ioannina. The authors cover devices made on polymer, paper and textile fabric substrates and which use electrochemical biosensing for detection. Lab-on-a-chip & microfluidic devices based on flexible substrates are very attractive given the low costs of the substrate and deposited materials, inexpensive and well established high volume manufacturing processes, and physical flexibility as an attribute for body-wearable devices.

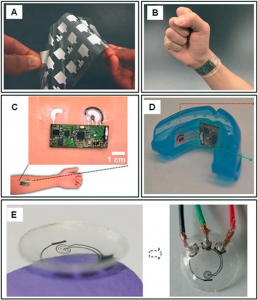

Sensor/device formats include patches, bandages and wristbands for dermal/transdermal sensing, dental mouthgards for salivary analyses, tooth patches for bacterial detection and contact lenses for tear fluid analysis. Analytical applications include immunosensing, glucose monitoring, bovine serum albumin (BSA) sensing, metabolite sensing, cancer marker detection and HIV detection. Deposition methods include lower-cost approaches such as screen printing, inkjet printing and electrodeposition for materials such as graphite, indium tin oxide, polyethylene terephthalate (PET). Polymer substrates include thermoplastics like polyethylene, polystyrene, PET, polypropylene, polycarbonate, cyclic olefin (co)polymers (COC & COP), thermoset polymers like polyimide, and photoresists. Filtre paper is the most common type of paper substrate, though newsprint is also mentioned. 3-D, folding or origami approaches are also discussed, as previously highlighted in this blog.