Interfacing with users and the real world is one of the many practical challenges facing any team engaged in technology-based product development. For microfluidics or lab-on-a-chip based products, this is nears the top of the list of challenges to be addressed early, starting at the duct tape/super-glue prototyping phases through to product launch. Interfaces need to be small, snug and low dead volume to reap the benefits of the miniaturised operations going on inside the microfluidic network.

Interfacing with users and the real world is one of the many practical challenges facing any team engaged in technology-based product development. For microfluidics or lab-on-a-chip based products, this is nears the top of the list of challenges to be addressed early, starting at the duct tape/super-glue prototyping phases through to product launch. Interfaces need to be small, snug and low dead volume to reap the benefits of the miniaturised operations going on inside the microfluidic network.

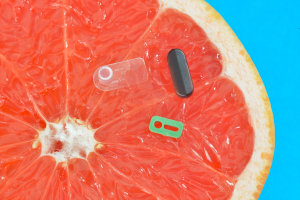

To this end, I thought I’d highlight what appears to be a convenient product offering from Precision Polymer Engineering. They seem to have very nicely crafted, very small elastomer components that might obviate the need to a) press the guy with the steadiest hand in the lab into service to cut Teflon gaskets, b) source those parts at volume once designs are frozen, etc. See image above from their recent tweet. They’ve produced a brochure that shows different elastomers, dimensions and standard parts on offer (gaskets, ferrules, o-rings, etc.).